Besuchen Sie uns auf folgenden Messen:

MD&M West 3.-5. Feb 2026

Plastindia 5.-10. Feb 2026

mehr >>>

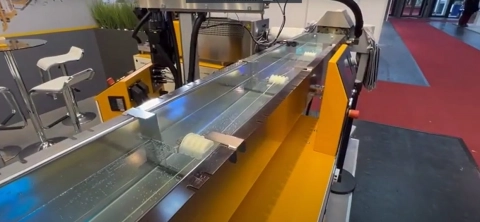

COLLIN Extrusions-anlagen weltweit Modulare Extrusionssysteme für Forschung und Industrie

COLLIN Extrusionsanlagen stehen weltweit für Präzision, Innovation und modulare Technik in der Kunststoffverarbeitung. Ob Labor, Pilotproduktion oder industrielle Fertigung – COLLIN entwickelt Anlagen für Forschung, Universitäten und Unternehmen.

COLLIN Weekend Service HotlineIn dringenden Fällen stehen wir Ihnen auch am Wochenende zur Verfügung

- Tel.: +49 (0) 171 / 23 62 64 5

- E-Mail: weekend(at)collin-solutions.com

PILOT LINE für Blas- & Flachfolien

Medizinische Schlauchanlage